HIWIN Single-Axis Robot

The HIWIN Single-Axis Robot module employs advanced standard manufacturing technology developed over the years.

The HIWIN Single-Axis Robot module incorporates advanced standard manufacturing innovations developed over the years. Both the ballscrew and magnetic slide design modules are internally developed and produced.

HIWIN proves to be relevant for a diverse array of automation tools due to its features, including easy installation, high precision, compact size, and various specifications.

The HIWIN Single-Axis Robot module employs advanced standard manufacturing technology developed over the years.

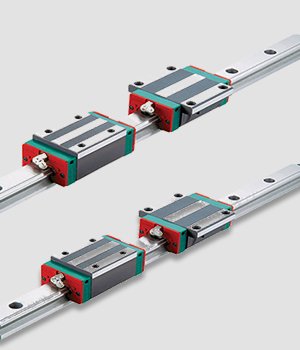

The EG series linear guideway is driven by a substantial load capacity and significant rigidity within its four-row pattern design.

The HIWIN precision Ballscrew delivers exceptionally smooth and precise motion, coupled with low driving force and high rigidity.

A nimble and compact articulated-arm robot with a wide range of motion to execute intricate positions.

Effective motion control is essential for the proper operation of numerous types of medical equipment.

Hiwin stands as a leading provider of complete turnkey systems tailored for the packaging industry.

Hiwin stands as a top supplier of turnkey systems designed for the packaging industry.

In an attempt to reduce the risk of human error and assist workers with hazardous or repetitive tasks, the overall automation industry is tasked with creating dependable automation technologies.

Metal fabrication involves manufacturing processes that utilize tools to bend, shape, saw, cut, and assemble metal sheets, plates, and blanks into a final product. Precision motion control is crucial for crafting accurate metal components, underscoring the importance of selecting dependable, high-quality motion control components from a reputable provider.